White Paperboard Business

We improve customer satisfaction by accurately understanding changes in demand structure and providing environmentally-friendly and high-quality products

SDGs closely relating to our business

Business Overview

Our division’s main products are premium white paperboard, special white paperboard, coated duplex board, cast-coated paper, etc. We have established a graded pyramid lineup of whiteboard products, in order to meet our customers’ diverse needs. The major use of our products is in commercial printing, which includes packages, catalogs, POP advertising, postcards, and publication covers. Most recently, we have been working on developments to incorporate new demand for primary food containers, alternatives to plastic containers, and packaging materials. Our production sites in Japan are at the Niigata Mill and Kanto Mill (Ichikawa and Katsuta) and overseas by Group company Jiangmen Xinghui Paper Mill, located in Jiangmen, Guangdong Province, China.

Medium-term Management Plan 2023 initiatives

The way forward with primary food containers and alternatives to plastic containers

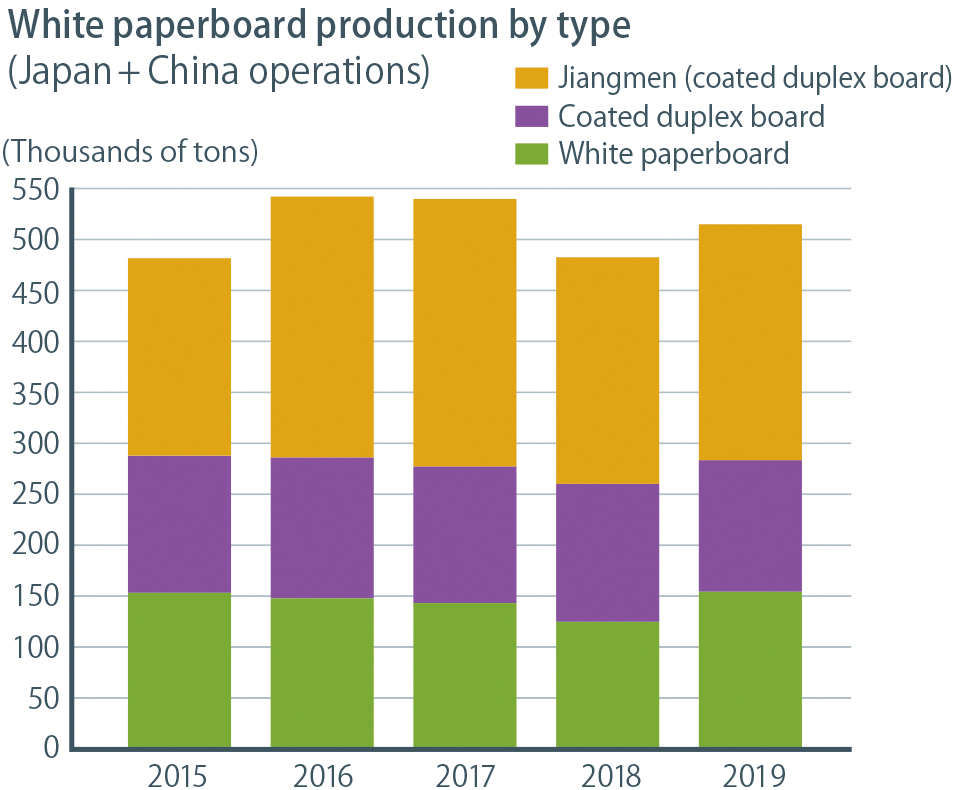

In 2019, total shipments in Japan of white paperboard by manufacturers was approximately 1.26 million tons with the Group accounting for about 260 thousand tons, or 20% of the market share in Japan. Although we have maintained our market share, shipments have fallen by about 10,000 tons from the previous year due to lower demand. Demand in Japan for white paperboard is strong in the food and pharmaceutical fields, which are the main uses of paperboard for paper containers, but users continue to cut costs by reducing food loss, reducing packaging, and switching to flexible packaging. The inbound effect has also shrunk after its peak in 2017. Also, due to a decrease in POP advertising and catalogs due to rethinking publishing and advertising expenses, the total volume is expected to continue to shrink. However, we anticipate new demand for primary food containers and alternatives to plastic containers, and we will continue to actively develop this field.

Building a system that can respond quickly to changes in the environment

With the start of our new medium-term management plan, we will seek to optimize the white paperboard business as a whole, build a system that can respond quickly to changes in the environment, and work to improve customer satisfaction. Specifically, we will focus on the following:

- (1) Further strengthen proposals to users, mutual visits, and technical cooperation to increase sales of white paperboard.

- (2) Promote efforts toward maintaining appropriate inventories. We will achieve efficient delivery by consolidating the products of the Kanto Mill (Ichikawa) at the i Missions Park (IMP) Ichikawashiohama warehouse, which started operation in October 2019. This will improve convenience for distributors and converters.

- (3) Promote the development of primary food containers and plastic alternatives with the aim of capturing new demand.

- (4) Contribute to the profits of the entire Group by sharing information and sales strategies with our Group companies, Hokuetsu Package and Hokuetsu Paper Sales.

Making the Kanto Mill an environmentally-friendly manufacturing hub

We are engaging in the following specific initiatives from FY2020:

● Discover market potential for our products and improve customer satisfaction Promote the creation of attractive

Promote the creation of attractive products by uncovering user needs and leveraging the superior quality our white paperboard

● Capture demand for alternatives to plastic containers and packaging materials

Move forward with proposals for paperboard-based primary food containers and packaging materials, and work with converters to expand sales in response to demands for alternatives to plastic

● Incorporate new product needs with the Group (Hokuetsu Package and Hokuetsu Paper Sales)

Further strengthen collaboration with Hokuetsu Package and Hokuetsu Paper Sales, who are close to users,accurately grasp product needs from consumers, and work on developing attractive new products

● Develop the Kanto Mill as a next-generation environmentally-friendly manufacturing hub

Take advantage of the location of the Kanto Mill in the Kanto region, which is the largest area of consumption and producer of used paper in Japan, and move forward with its conversion as an urban mill to an environmentally-friendly manufacturing hub.

Focus & Topic

New i Missions Park (IMP) Ichikawashiohama warehouse begins operations

Operation of the new i Missions Park (IMP) Ichikawashiohama warehouse in Ichikawa, Chiba began in October 2019. The purpose of the warehouse is to consolidate the product inventories of the Kanto Mill (Ichikawa), which are stored at multiple locations across the Kanto region. By consolidating product inventories, items that were previously shipped from multiple locations will be stored in one location, improving our shipping efficiency and costs. Improving our shipping efficiency will also help address the recent shortage of truck drivers. In considering consolidation of our warehouses, we carefully gathered information in advance, and found that the IMP Ichikawashiohama warehouse was most suitable due to the fact it is close to the mill, has good access to delivery destinations and multiple road options, and has favorable operating costs. We will continue to support our customers in delivering better products with greater peace of mind and safety.