Paper Business

We will strengthen our competitiveness by giving overall optimal considerations while responding to rapid changes in the market environment

SDGs closely relating to our business

Business Overview

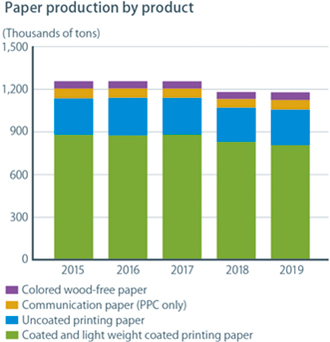

The main product of the Paper Business is printing and communication paper used for books, magazines, catalogs, and brochures. Coated paper and uncoated printing paper are our key products in our product line-up, with production of coated paper in FY2019 having the third highest share in Japan and uncoated printing paper taking the second highest share. Furthermore, our colored wood-free paper with its tradition and rich product line-up is a top brand in Japan, which shows that it is loved by a wide range of customers.

Medium-term Management Plan 2023 initiatives

Thoroughly strengthening the competitiveness of the Niigata and Kishu Mills and the Sales Department

Our shipment of printing and communication paper in 2019 exceeded its previous year, especially in the first half. We drew higher orders because our production were relatively favorable, on the other hand there were multiple natural disasters and supply instabilities at other manufacturers in 2019. Export sales were 210,000 tons per year due to the deterioration of international market conditions owing to international trade friction. This was a very severe export environment and we did not reach our target of 300,000 tons per year. For 2020, based on Medium-term Management Plan 2023, the first step toward realizing “Vision 2030,” the new long-term management vision, the Niigata Mill, Kishu Mill, and the Sales Department are aligned in the same direction working together, and engaged in full-fledged efforts to enhance our competitiveness in order to respond to rapid changes in the external environment. Specifically, we will focus on the following:

Paper Business Division

With demand declining significantly due to the novel coronavirus pandemic, safety and compliance are our top priorities, and we will work to maintain firm sales prices in Japan and continue stable operations and

Niigata Mill

- (1) Establish an accident-free and disaster-free mill by striving for thorough compliance and independent health management.

- (2) Prevent operational troubles and large equipment failures with planned maintenance.

- (3) Give optimal consideration in response to the decrease in domestic and overseas demand and cut costs to maximize profits.

- (4) Promote SDGs through energy, pulp, and papermaking from chips.

Kishu Mill

- (1) Complete the implementation of risk assessment measures and draw up preventive measures for disasters, the environment, and operational trouble.

- (2) Strive for thorough compliance where all employees share awareness and responsibility as members of society.

- (3) Strengthen quality control, strive to prevent the occurrence of defective products, and visit customers individually to work to develop new markets and new products.

- (3) Work to enhance competitiveness through optimal production in line with changes and challenging cost improvements.

Sales Department

- (1) In the face of declining demand, maintain sales prices in Japan and engage in sales activities with an awareness of the industry share of our main products.

- (2) Conduct regular visits of our users by staff at our mills to strengthen relationships and respond appropriately to customer requests to generate stable sales.

- (3) With exports, given that demand in Japan cannot be expected to expand, aggressively promote direct trade to develop sales measures that accurately capture overseas market trends, and further strengthen relationships of trust with customers to expand sales channels.

- (4) Switch to paper materials as a substitute for plastic packaging and expand sales in consideration of environmental issues.

Focus & Topic

Aggressively rolling out a further modal shift

We were awarded the “21st Logistics Environmental Conservation Activity Award” for the transportation (modal shift) of DIP pulp at the Kishu Mill, which started in July 2019. Also, part of the transportation of products from the Niigata Mill to northern Kanto, which used to be done by trucks, was converted to Japan Railway Container Transportation in March 2020. Until August 2020, rolled products were transported by rail stacked in 12 ft containers, and are then transloaded (rolled) onto trucks at a warehouse near the freight terminal before delivering them to users. From September, we have been able to use our own privately-owned 20 ft containers to transport the products to users without transloading them. We are also considering round trip freight in the future, and are aiming for so-called “container round use.”

Expanding for the growing demand for process application products

In response to the global demand for plastic alternatives, the export of base paper for paper cups and paper straws produced at the Kishu Mill has been growing in recent years. Exports of base paper for notebook, paper bag and thermal paper for China are also growing, and we have made upgrades to meet the required quality. We are in the process of rapidly expanding our lineup in response to rising demand. We will move ahead with the development of products for new applications both in Japan and abroad, and aim to increase our sales volume based on these manufacturing technologies.