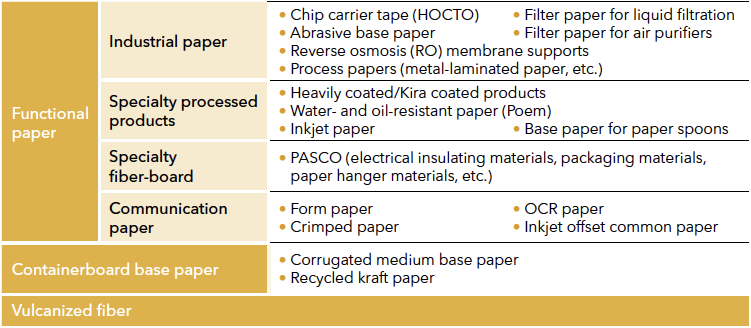

Performance Materials Business

Major Initiatives and Achievements in FY2024

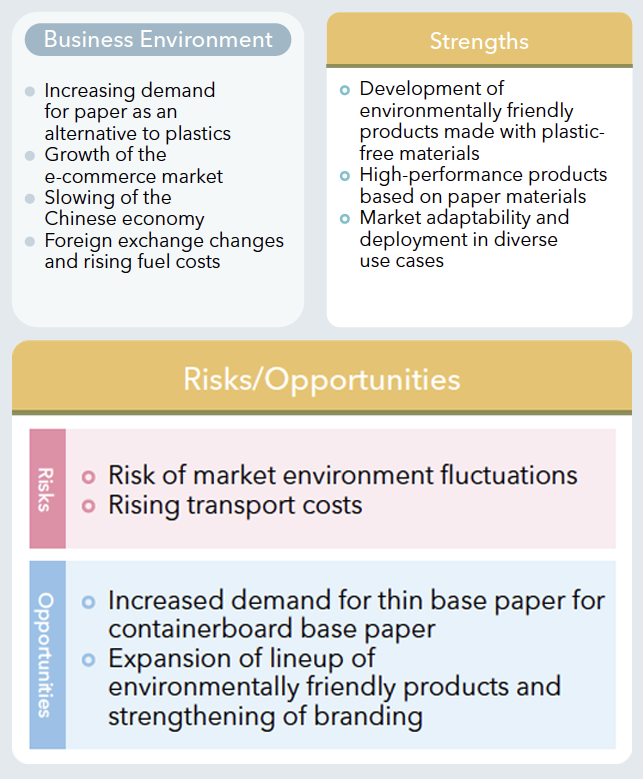

Demand remains strong for products adapted to structural changes in market needs

In FY2024, demand recovered overseas for base paper for chip carrier tape used in electronic component transport. Sales of crimped paper for postcards and food packaging materials for convenience stores increased. Cases of adoption of PASCO, a plastic-free material that excels in workability and moldability, are expanding. Sales volume of containerboard base paper decreased under sluggish demand domestically and overseas. However, we worked to maintain export sales volume by expanding beyond general core applications to packaging applications as recycled kraft paper. In the area of vulcanized fiber, we increased sales, particularly export sales, despite soaring prices of raw materials by maintaining U.S. sales and other stable orders with existing customers.

Applying papermaking technology in product development

Our Group is carrying out new product development and quality improvements in existing products in response to customer needs and market changes, including demand for plastic-free products. In FY2024, our electromagnetic noise suppression sheets made with nanocarbon were adopted for use in industrial equipment noise countermeasures. We also developed a new electromagnetic wave absorber through the application of papermaking technology. We are also continuing the development of biodegradable filters.

Major products (brands)

1 Hanger hooks made with PASCO

2 Paper cups made of Panse environmentally friendly paper packaging material

3 Electromagnetic noise suppression sheet

Business Strategy Going Forward

Shift to a supply structure matched to needs for environmentally friendly products

With demand and markets for traditional products expected to contract, we face a pressing need to shift to a production and supply structure capable of adapting to new needs. We will expand sales activities with renewal of product lineups in mind, while continuing our efforts to explore new applications including plastic-free products that meet the needs of the times. Furthermore, demand for environmentally friendly products remains strong. Our water- and oil-resistant paper Poem, free of fluorine-based agents, is attracting attention as a paper-based barrier material amid growing movements to regulate PFAS substances. We intend to add a thick grade to the product to expand into packaging applications. To reduce environmental impacts from containerboard base paper, we will focus efforts on the production and sale of thin and high-strength reinforced media that maintain strength even at unchanged thickness and weight.

Development of higher-added-value products

In our existing products, we will work to enhance product value through the improvement of quality and addition of high functionality. We will undertake the development of Panse, oxygen barrier paper, and other environmentally friendly paper materials aimed at bringing plastic-free and reduced-plastic products to every field. In the area of containerboard base paper, we will take advantage of the features of the Niigata Mill’s No. 6 paper machine to continue developing products that meet needs beyond corrugated medium applications, including heavy packaging, light packaging, and impregnation applications. In new fields, we will tackle the development of higher-level functions and new applications for electromagnetic wave absorbers. We also engage in joint research with universities. While analyzing the electromagnetic wave absorption mechanisms of our developed products, we are conducting research that can be presented externally so as to appeal to engineers at electronic equipment manufacturers and others. In one of our industry-academia collaborations, we are working with the Center for Disaster Medicine and Education at the Niigata University Faculty of Medicine to develop paper products that incorporate feedback from disaster-related medical care practitioners. Our aim is to use products including our PASCO special fiber board, which is used even in stretchers, and Poem, which is resistant to oil as well as water, in the development of products that are friendly to disaster victims and medical care practitioners alike.

Rescue Board, a lightweight, durable emergency stretcher made from paper

Adoption of our cellulose vulcanized fiber in the Shizuoka Mokumaru electric vehicle

Our subsidiary Hokuetsu Toyo Fibre Co., Ltd. produces vulcanized fiber made from natural cellulose, handling all processes from base paper to finished products. Vulcanized fiber has characteristics of paper but is partially converted to cellulose nanofiber (CNF) through chemical treatment. Exhibiting far greater strength than paper, it has been adopted in numerous industries for applications including electrical insulators and polishing substrates. In 2024, it was also adopted for use in the cargo space and floor materials of the Shizuoka Mokumaru electric concept vehicle made using wood from Shizuoka Prefecture. In February 2025, the material received Fuji CNF Brand Certification (6th Round) from the city of Fuji in Shizuoka Prefecture. Amid modern-day demands for plastic-free products and growing attention toward plastic alternatives, we will continue to advance the development of environmentally friendly products while enhancing our corporate value.

Vulcanized fiber used in the cargo bed of the Shizuoka Mokumaru vehicle