Paper Business

Major Initiatives and Achievements in FY2024

Build an optimal production and supply structure

In FY2024, we experienced impacts from declining paper demand amid the digitalization of advertising, mail order catalogs, and other media. However, by ensuring consistent product quality and strict adherence to delivery schedules, and through our efforts to maintain and improve our relationships with printing companies and other key buyers, we maintained the market shares of our mainstay printing paper and color wood-free paper, resulting in higher sales. In the area of product logistics, as a part of our strategic business alliance with Daio Paper Corporation, we cooperated with our subsidiary Hokuetsu Logistics Co., Ltd. to promote enhanced transportation efficiency centered on “round transport” of trucks and 20ft containers.

Grow share in overseas markets

Our paper export volume reached 290,000 tons in FY2024, a 20% increase year on year. This earned us the top share among Japanese paper manufacturers in the printing paper segment. Demand for our mainstay coated woodfree paper grew under economic growth in the Indian market, while active promotion of sales to the U.S. further contributed to increased exports. In uncoated woodfree paper, we have already transitioned to a sales structure focused on applications for processed base paper, with both price and volume remaining firm.

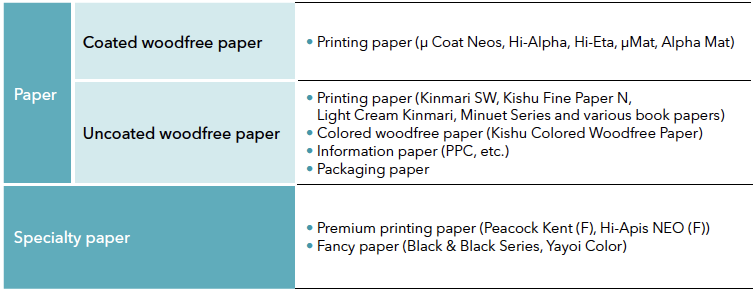

Major products (brands)

The No. 9 paper machine at the Niigata Mill, a massive 223 meters in length, carries out integrated processes from base paper making to coating to produce roll paper with a width of 10m and a length of 180km.

Business Strategy Going Forward

Recover domestic market share through the establishment of a flexible production and transport structure

In the domestic market, we aim to secure our sales share amid ongoing sluggish demand by accurately reading market trends while spotlighting our high-quality and environmentally friendly production structure as a competitive advantage. To enhance the stability of our production structure, we will also engage in production instruction, order-taking, and sales activities that fully leverage the individual characteristics and strengths of our mills. In the area of logistics, we will advance our “round transport” partnership with Daio Paper Corporation. We will also consider new measures that include transport using containers and coastal shipping vessels and the shared use of both companies’ warehouses to further boost transport efficiency and create synergies between the two partners.

Promote new market development through efforts to further expand overseas market share

In overseas markets, we are strengthening relationships with customers with whom our products have earned strong trust, while taking advantage of the unique competitiveness of our mills in initiatives aimed at prioritizing stable supply. We will also focus on product development including processing and packaging applications as we strive to continuously expand exports and contribute to maintaining high operating rates of our mills. Our Ho Chi Minh City office will focus on market research and information collection for direct transactions with overseas customers while undertaking structural reinforcement that encompasses the Vietnamese and Thai markets.

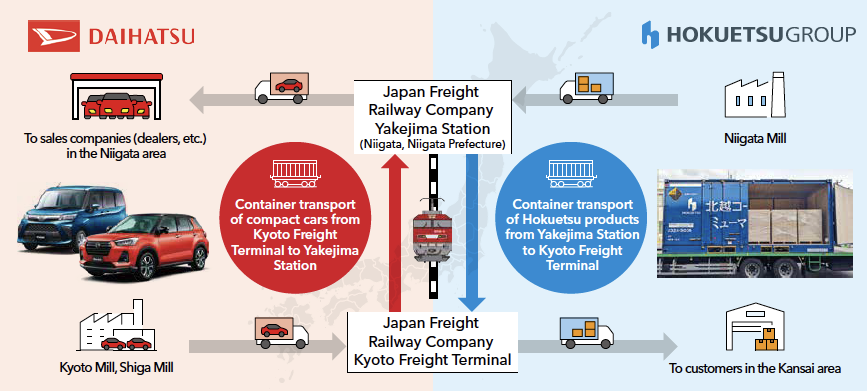

Construct a sustainable transport system through railway-based, cross-industry round matching transport

We are working to reduce the environmental impacts of our logistics through means that include a modal shift to railways for product transport. In February 2025, we began cross-industry round matching transport* utilizing our 20ft containers in cooperation with Daihatsu Motor Co., Ltd., NIPPON EXPRESS Holdings, Inc., and Japan Freight Railway Company. In the past, we had used these containers for the railway transport of roll products from the Niigata Mill to the Kansai region, but the return transport of empty containers posed an efficiency issue. Our new trial project to carry compact automobiles from Daihatsu Motor Co., Ltd. on the containers’ return route is expected to increase transport efficiency and further reduce CO2 emissions. We will continue working to build efficient transport systems and contribute to the realization of a sustainable society.

* Round matching transport is a method of raising container loading rates on outgoing and return routes. After cargo is unloaded at its destination, the containers are not returned empty but are loaded with suitable cargo for return to the point of departure. This enables the reduction of costs and environmental impacts.