Performance Materials Business

Promoting strategies for each business and focusing on high value-added product development and stable production

Performance Materials Sales Department

| Business strategy | Status of efforts in FY2022 |

|---|---|

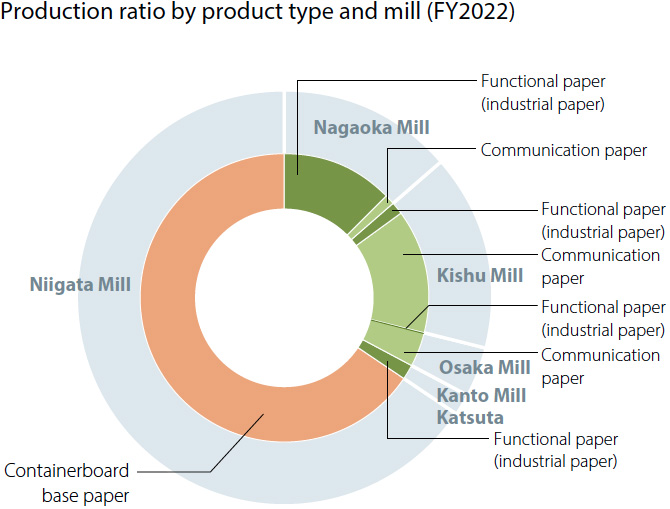

| Efforts related to measures to build a system to produce and sell growth products from a global perspective | We are considering expanding production capacity to meet demand to permanently maintain and expand the market share of AGM battery separators made by Dumas, a French group company. In addition, the Nagaoka Mill produces AGM battery separators for the Japanese market. |

| Capture demand for alternatives to plastics | Our rigid fiberboard PASCO® is used as an alternative for plastics in the hooks and hangers of major apparel companies, and efforts are being made to recycle these items collected at stores into PASCO®. We have also started efforts to replace plastic parts in store fixtures with PASCO®. |

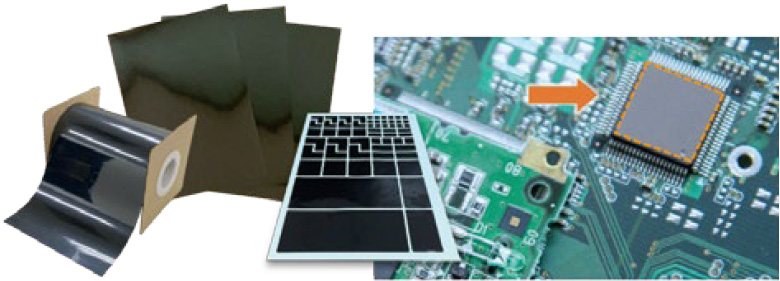

| Develop businesses that leverage the strength of the Group’s integrated production from base paper to processed products | Demand for HOCTO®, a base paper for chip carrier tape used to transport electronic components, is expected to increase in the mobility field. Using the pulp produced at the Niigata Mill as the main raw material, we produce base paper at the Nagaoka Mill and Kanto Mill (Katsuta), and process it into chip carrier tapes that meet customer needs. Part of this process is also done by our Group company in China, Shanghai Toh Tech, creating an integrated supply system within the Group. |

Containerboard Sales Department

| Business strategy | Status of efforts in FY2022 |

|---|---|

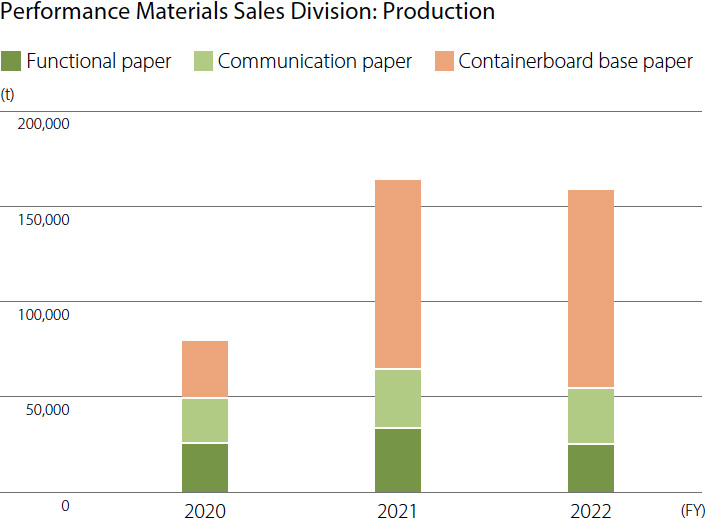

| Deepen relationships with customers and expand the basics of production and sales in the containerboard base paper business | We quickly and accurately capture needs and reflect them in product development, production, and sales through direct dealings with customers. In FY2022, we achieved production and sales of over 100,000 tons in Japan and for export. |

| Promote the improvement of production efficiency and improve profitability at an early stage | We are working to improve production efficiency by improving the per unit of raw fuels and expanding daily production. In addition, to accelerate improved profits, we are focusing on the development, production, and sales of high value-added products, centered on thinner base paper, which is our specialty. |

Paper Cup Business Development Office

| Business strategy | Status of efforts in FY2022 |

|---|---|

| Restructure our business portfolio and study new fields and businesses | In October 2022, we created a new organization, the Cup Business Development Office, within the Performance Materials Business Division. We are delving deeper into cup paper development projects and working with Group company Hokuetsu Package to offer concrete proposals using processed paper. In addition to being used for paper cups, we are also focusing on proposals for replacing plastic containers with paper ones in response to needs for plastic-free products and products that use less plastic. |

Product Development Office

| Business strategy | Status of efforts in FY2022 |

|---|---|

| Strengthen business by deepening cooperation among Group companies | In collaboration with Hokuetsu Package and Hokuetsu Paper Sales, we are continually proposing paper packaging materials as an alternative to plastic. As a result of repeated consultations with potential customers, we were able to realize commercialization in several instances. Additionally, the electromagnetic noise suppression sheet currently under development is being evaluated by end users. |

Actively offering environmentally friendly products such as alternative uses for plastic packaging materials

- The Performance Materials Sales Department strives to expand the market share of products that require outstanding functionality, such as environmentally friendly products that contribute to the reduction of CO and the volume of plastic waste, as well as products related to hygiene management and advanced technology.

- The Containerboard Sales Department aims to build a strong profit structure by strengthening stable production and sales systems. We also work to further reduce the weight of thinner base paper and address the need to reduce CO emissions at the production and logistics stages.

- The Paper Cup Business Development Office, which was newly established in October 2022, and the Product Development Office, whose name was changed from the Performance Materials Development Office in April 2023, are working on proposals to replace plastic packaging materials used for food products with paper.

Performance Materials Sales Department

Expanding market share and stable supply of products related to environment, hygiene, and advanced information technology

To meet the growing need for environmentally friendly products, we proactively propose paper that can be used as a substitute for flexible packaging for food as an alternative to plastics. We also promote the development of new applications for our rigid fiberboard PASCO®. We have also built a stable supply system for HOCTO®, a base paper for carrier tape that transports electronic components, which is an advanced information technology-related product that is essential for the development of social infrastructure, battery separators, filter media for hygiene-related products, microfine®, and RO membrane backings. In the area of functional communication paper, we actively engage in sales activities for crimped postcard paper.

Containerboard Sales Department

Working to lower the weight of base paper and addressing the need to reduce CO emissions during production and transportation

In order to further expand and develop our business in the future, we aim to build a strong profit structure by stabilizing our production system and strengthening our sales capabilities. Regarding sales in Japan, in response to the recent rise in the price of raw materials and fuel, we have revised our prices twice over the past two years with the understanding of our customers, which has contributed to improved profitability. In addition, we will further expand sales of thinner base paper, which is our forte, by addressing the need to reduce CO emissions during production and transportation by reducing weight. Exports are lackluster due to sluggish demand in China, our main export market, but we aim to differentiate ourselves from other companies by implementing quality designs that incorporate local needs and continue to strengthen our sales capabilities.

Paper Cup Business Development Office

Promoting market research, developing cup base paper, and proposing base paper for paper containers

We will increase our ability to propose products to customers such as domestic cup molding manufacturers who are highly environmentally conscious and expand our projects by leveraging our strength in the ability to produce base paper with low CO emissions. Additionally, we will focus on market research from our users’ perspectives, connect society’s needs for plastic-free products and products with lower plastic content to our proposals for paper food containers, and aim to expand our business through collaboration with Hokuetsu Package. At the same time, we will proceed with specific proposals and commercialization tailored to the quality and characteristics of each cup base paper, such as paper-based and white paperboard-based paper, which will help us establish quality at an early stage.

Product Development Office

Commercializing paper food packaging materials and proposing electromagnetic wave shielding materials

Due to a reorganization in April 2023, we changed the name from “Performance Materials Development Office” to “Product Development Office.” In response to the trend of replacing plastic food packaging materials with paper to reduce plastic waste, we have commercialized paper materials such as “Panse” that is suitable for packaging machines and are offering them to customers. In electromagnetic wave shielding materials, we will further develop electromagnetic noise suppression sheets that are effective for large-capacity communication cables and next-generation communications such as 5G.